When it comes to creating professional printed pieces such as business cards, formal invitations or certificates, you may feel that your creativity is limited due to the nature of the job. While you might not be able to have as much artistic freedom with these prints, there are several ways to make your final piece visually interesting without “overdoing it.”

In this scenario, our printing experts will often recommend embossed or debossed printing, as the designs can be anything from simple to complex. Learn more about embossing and debossing, and how these techniques can make an impact on the quality of your work!

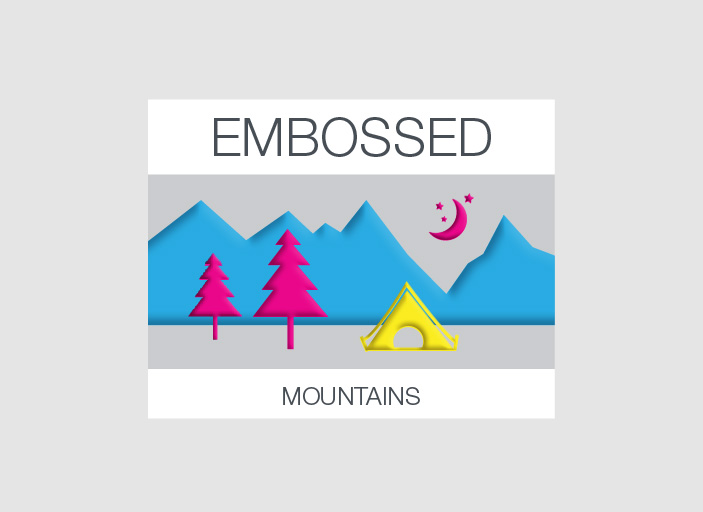

What is Embossed Printing?

Embossing is a technique used to raise a design onto your choice of paper, or other materials such as vinyl or leather, after they are printed.

The embossing process begins with the creation of a metal die and counter-die (or “male and female” dies) of your logo, image or artwork. These dies are used to transfer an image onto your materials. Depending on the strength of the metal used to create your dies, they can be reused on different print jobs for a significant amount of time.

During an emboss, the printed material fits between the die and counter-die. With the combination of heat and pressure, an exact copy of your design is pressed into the material, resulting in an embossed print. This method can be combined with other techniques as well, applying ink or foil to the raised area. However, if the design is left as is, it is called a blind emboss.

While creating an embossing die is typically a one-time expense, it can add production time and charges to your printing process. Ask your Metzgers account manager for details on the timeline of your design and related cost.

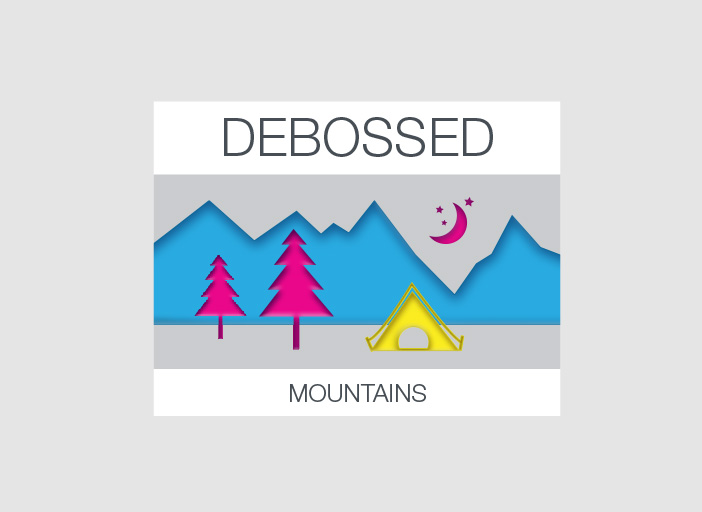

What is Debossed Printing?

Debossing is essentially the opposite of embossing, leaving a depressed imprint of your design in the material of your choice. Your design is printed directly on the material so that the area around the die impression can be raised, rather than raising the logo or image itself.

The debossing process begins the same way as embossing—with the creation of a die and counter-die of your desired image, logo or design. Debossing can also be done with or without ink, and in combination with other printing techniques such as foil stamping or offset printing.

As mentioned, be sure to ask your Metzgers account manager for further details on cost and design timeline.

Embossing or Debossing: Which to Choose?

The technique you decide to use will depend on what you want your final product to look like, and at times, the type of material you wish to emboss or deboss. With either technique, a designer has the ability to be as creative as they’d like! Simple or complex, the method of impressing of depressing an image onto your materials can have a striking impact on your final product.

In addition to emboss and deboss printing, our account managers are available to help you organize any project you have in mind—with your goals and budget taken into consideration! If you would like recommendations, or have any questions about embossing and debossing, contact the experts at Metzgers by calling 419.861.8611.